Unsurpassed. No other word can adequately describe the Glacier High Temperature Ceramic Coating range.

Formulated to withstand temperatures of over 2,000 degrees Fahrenheit and thermal shock from those temperatures directly into water with no adverse effects…

Our Five-Year Standard Powder Coating Guarantee:

We’re excited to extend our work guarantee to up to five years, protecting against corrosion from the inside out, paint fading, and surface lifting for most powder-coated items! Our meticulous process delivers the highest-quality results, featuring thorough blast cleaning, precise phosphate washing and masking, a zinc-rich powder-coat primer, and a high-quality powder-coat finish.

CERAKOTE

For those of you interested in our Cerakote options, we recommend keeping your items looking their best with some regular care! A simple wash with standard car shampoo will do wonders, and it’s essential to quickly tackle any road salt or other contaminants. To maintain the integrity of the coating, avoid cleaners containing harsh acids or abrasive substances like T-cut, as these can damage the finish.

Keep in mind that while your items are durable, exposure to road debris, grit, and tyre spray may influence the surface colour over time.

For optimal protection, we suggest applying a plasma base coat to any exposed parts. We proudly offer a two-year guarantee for our Cerakote items!

Cast Iron / Mild Steel Items:

Additionally, we provide an optional alloy plasma metallization coat to enhance our two-year guarantee for cast iron or mild steel products, such as manifolds and turbo housings. This extra layer not only minimises heat loss but also effectively conceals minor corrosion

damage after our blast cleaning process, resulting in a unique, slightly textured finish. Our warranty covers excellent surface performance and burning when you choose a suitable high-temperature coating from our curated product range, with a standard one-year warranty for Cerakote single coat, extending to two years with the base plasma coat!

At Maldon Shot Blasting & Powder Coating Ltd, we always prioritise quality over cost. While our prices may be higher than some competitors’, choosing our services means investing in reliability and durability that brings long-term value.

We believe in open communication, so you can trust that we’ll keep you updated on any developments throughout the entire process. Your satisfaction and the longevity of your products are our absolute top priorities!

Additional Information:

Please note that our warranties do not cover accidental damage or staining caused by road pollution, road salt, burnt-on tar, or heavy grit.

Warranties apply only to items that are in good condition before any work begins.

Guarantees are subject to the general condition of the items, and there may be cases where we can’t offer any coverage.

If you experience any issues, please reach out to our office via email, including a description of the issue and photos. We’re here to help!

Please visit our main website for further information: www.msbpcl.co.uk

New to our range of ceramic coating range, Graphite black...

Performs at temperatures above 1000ºc

High Performance Ceramic Coatings

-

wood and pellet burning stoves,

-

fireplace inserts

-

Exhaust systems (i.e. stove exhaust pipes)

-

Barbecues

-

Lighting fixtures

Warning… these products must have time to cure to perform at it’s best, so please allow five full days before running up to working temperature, failure to do so will void any guarantees.

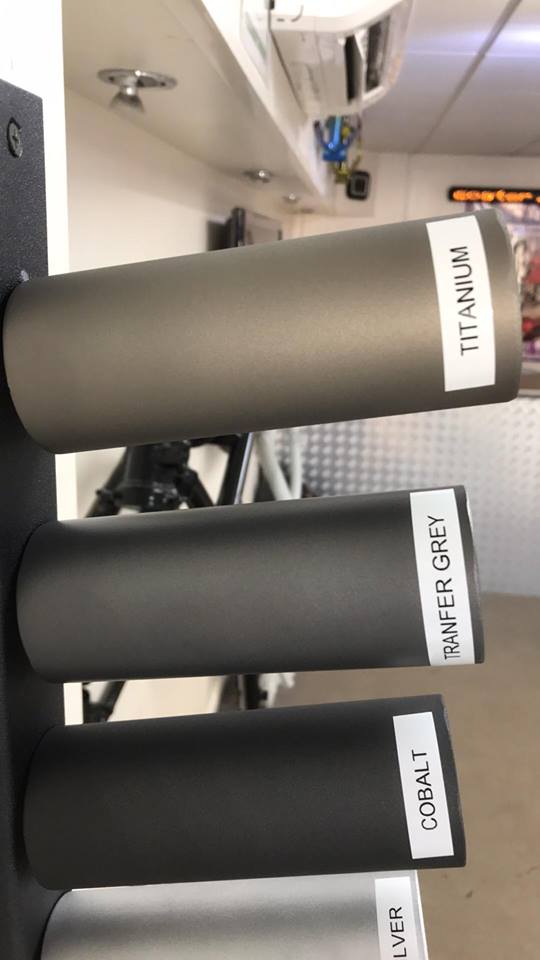

Colbolt Ceramic Coating

Our ceramic coatings have become very popular.

Great colours and a rich matte finish.

A very thin, durable, high tech coating.

This is the same product that’s used on exhaust headers & systems.

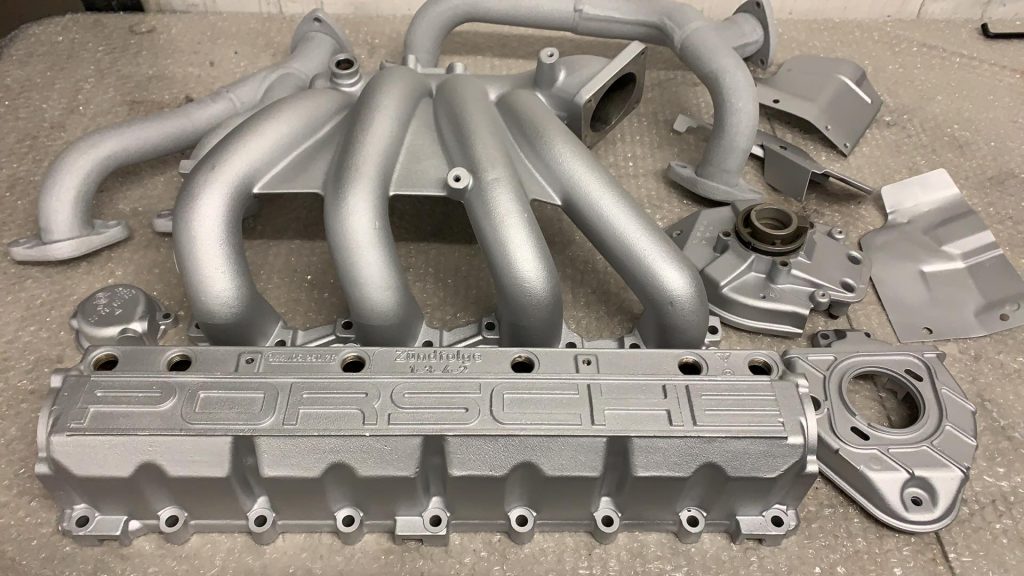

Porsche parts finished in Glacier silver ceramic coating.

New Titanium finish high tempreture coating

Brilliant finish for that special touch for engine casings, exhuast systems.

Can be applied to alloy wheels, steel frames or high heat surfaces.

Three new ceramic coatings

Examples of our High Performance Coating work….

Powder Coating Surface Preparation

Shot blasting is often the unsung hero in restoration projects — yet its impact cannot be overstated.

Ceramic Coating Frequently Asked Questions ( FAQ)

Ceramic Coating is the most advanced and durable thermal barrier on the market. Available in a variety of colours, ceramic coatings give your project a personalised touch that will make your project superior in both appearance and performance vs. the competition.

Advantages of Plasma Coating

The manifolds shown have been pre-treated with our plasma coat system and a further ceramic coat applied.

Finished in Cerakote Ceramic Glacier Silver

Nice little job – finished in Cerakote Ceramic glacier silver.

Extra Long Term Protection for Exhaust Systems

Long term protection… after blast cleaning, we apply our plasma coat system. This lays down a pure metal base over the blasted surface and goes a long way to protect any exhaust for many years…

Cerakote Ceramic Finish

Blast cleaned with virgin clean blast media, clean and prep work & Cerakote ceramic finish applied…

Ceramic Coated Headers & Exhausts…

Looking to ceramic coat headers or exhausts?

We have a range of products to cover most requirements. Our work also includes a two-year guarantee in most cases.

High End Powder Coat Protection

Advanced ceramic protection for a refined, understated finish. Guards against extreme temperatures, weather exposure, and contaminants.

Ceramic Coating With our Rework Guarantee

High temperature ceramic coating that comes with our rework guarantee. We also offer an extremely tough and rugged base coat for harsh environments. Visit msbpcl.co.uk for more information.

Ceramic Coat Prep Work

Prep work – aqua blast cleaning to bring back that almost new look, clean & dry. And apply a clear ceramic coat to keep it looking good for years to come.