High Performance Clear Ceramic Coating.

The strongest clear coat on the market. It leads the industry in hardness, chemical resistance, wear performance and UV stability. As a high gloss, ceramic clear coating, MC-160 can be used as a topcoat over several materials such as metals, paints, composites, plastics, hydro graphics.

Performance & recommend use of MC160.

- All metal types including

- Polished metals

- Hydro graphics

- Paints

- Composites & Fiberglass

- Plastics

- PVD

- Thermal Stability to 1100F (593 cent)

Cerakote is a ceramic based finish that can be applied to metals, plastics, polymers and wood. The unique formulation used for Cerakote ceramic coating enhances a number of physical performance properties including abrasion/wear resistance, corrosion resistance, chemical resistance, impact strength, and hardness.

The Cerakote H Series is probably the most common coating available. It isn’t as tough as the Elite series during lab tests, but it will still fight against corrosion and chemicals better than other available coatings, and it’s so popular that you can get the protection you need in almost many colours, even gold. The H series is also a bake-on application, so no melting plastic pieces.

In general, if you are trying to add a little flair, the H series is perfect for your project. The upshot over most other decorative mediums, of course, is that you are adding one of the toughest layers of protection along with the colour. There’s a reason it’s so popular. Fit and finish on internal pieces will require some extra attention, as the 1 mil thickness of the layer is enough to tighten tolerances on moving parts. The H Series works well on everything from dive watches to fishing gear, to firearms. On parts where it’s possible, multiple layers can be added to handle wear better over time.

Magnesium alloys can be nickel-plated followed by CERAKOTE® and selective masking to meet complex design requirements. For example, an electronic device housing made from magnesium can be nickel-plated all over then Cerakoted® on the outside. The result is electrically conductive and EMI shielding on the inside with a decorative, corrosion-resistant and distinctively high-end look and feel you have to experience to believe.

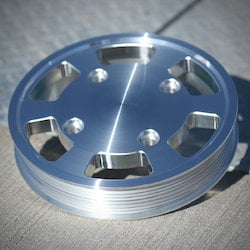

Application to all metals- Hydro graphics-composites & fibreglass- Plastic-, PVD ( vacuum deposition materials) Temperature stability up to 260 degrees centigrade. Chemical resistant. Ideal for polished parts as engine casings, rims etc.

Protected by a clear coat ceramic.

The strongest clear coat on the market. It leads the industry in hardness, chemical resistance, wear performance and UV stability. As a high gloss, ceramic clear coating, MC-160 can be used as a topcoat over several materials such as metals, paints, composites, plastics, hydro graphics.

Performance & recommend the use of MC160.

All metal types including

Polished metals

Hydro graphics

Paints

Composites & Fiberglass

Plastics

PVD

Thermal Stability to 1100F (593 cent)

Did you know Ceramic clear coat offers many advantages over standard clear wet lacquer coats, Very tough High chemical resistance against wheel cleaning products, break dust etc.

Honda front fork casements finished in ceramic silver sliders coated with ceramic clear coat.

Ceramic coat for aluminium. MC5100

CERAMIC Clear – Aluminium MC-5100 has been specifically engineered for Aluminium products.

Application for alloys of aluminium, including magnesium alloys. Other applications include polished, brushed, raw & anodized aluminium used in architectural, automotive, industrial, consumer goods.